From the variable speed drive voltage pulse may be a coupling between the motor stator and rotor, which may lead to a voltage to appear on the rotor shaft.When the rotor shaft voltage exceeds the insulation voltage of the bearing grease, may appear high voltage arc or edm, leading to a motor bearing race corrosion pitting and groove, this damage can lead to premature failure.This use case describes how to useMDA - 550 Motor Drive AnalyzerVoltage probe to measure the motor shaft and the shaft voltage discharge event.

Shaft voltage discharge

Capacitive coupling between the motor stator and rotor voltage on the motor shaft.So bearing in the motor will not only by the wear, due to the rotation of the shaft will be due to the current flow through the motor shaft bearing ground under wear.By sine wave ac power of motor can be about 1 to 2 V voltage shaft/bearing to stand.By variable frequency drives (VFDS), however, the rapid transformation of wave power supply of the motor can be up to 8 to 15 V voltage shaft/bearing to stand.This level of voltage can be overcome bearing grease insulation properties of the resulting spark may cause pitting corrosion, erosion groove, melting pit, and eventually lead to premature bearing and motor fault.

Carbon brush shaft voltage probe

Capacitive coupling between the motor stator and rotor voltage on the motor shaft.So bearing in the motor will not only by the wear, due to the rotation of the shaft will be due to the current flow through the motor shaft bearing ground under wear.By sine wave ac power of motor can be about 1 to 2 V voltage shaft/bearing to stand.By variable frequency drives (VFDS), however, the rapid transformation of wave power supply of the motor can be up to 8 to 15 V voltage shaft/bearing to stand.This level of voltage can be overcome bearing grease insulation properties of the resulting spark may cause pitting corrosion, erosion groove, melting pit, and eventually lead to premature bearing and motor fault.

Measuring equipment

MDA - 550 is designed to quickly and easily detection and elimination of the three-phase and single-phase inverter motor variable frequency drive system's all sorts of common problems.Besides 4 channel portable oscillograph and recorder function, specific motor driven analysis function also provides procedural step by step with screen information connection setup guide.So easy to configure analyzer, which can be from the power input to the motor variable frequency drive measure, including shaft voltage measurements.

Shaft voltage peak value can change very fast, and even lower than microsecond range.雷竞技appFluke MDA - 550 with 500 MHz high bandwidth and fast sampling rate (up to 5 G sample/SEC), make it very suitable for measuring of shaft voltage of rapid change.

The measured results

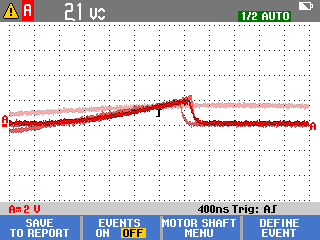

The default motor shaft voltage measurements show that the voltage waveform on the shaft itself.The top of the screen shows the peak voltage is pointed out that capture the waveform of the maximum level, this shows that the shaft high voltage level.However, these rapid discharge frequency of can't use this way to determine.With "open" function, MDA - 550 can be displayed according to predefined minimum voltage difference and maximum time record of the discharge waveform.

Shows the result will update to capture a steeper rise or fall time of each waveform, and detect the number of events per second.Discharge waveform will appear to the increase of the voltage, then the discharge moment shows a clear of the vertical electric wire.Detailed analysis to the capture of waveform, MDA - 550 provides a "replay" function, the screen buffer can capture the last 100 waveform.Screen can choose alone, or show for animation.

For more than 15 V voltage discharge and short transient time 50 nanoseconds, said discharge it might damage the bearings.However, this alone is not enough to determine the potential damage of bearing, because there are many other factors influence this.

If the shaft of the detected voltage is too large, it is suggested that by adjusting cable, grounding, drive parameters or lubricating oil to reduce the discharge voltage.If the above suggested that cannot or will not help ease the problem, you can choose to use shaft earthing device or insulated shaft.By comparing the changes before and after the record number of events, can easily understand the shaft voltage effect of mitigation measures.

Want to know more information?

Please fill out the short "demo request" list, we will contact with you, and arrange the qualified fluke engineers personal presentation for you.You will be in your place of work opportunities for the obtaining of trial instrument personally, specifically for what you need.You will know how easy it is to use our instrument, and we will also train and guide you how to use the instrument and the corresponding accessories.So, you must choose when buying real instrument for you, and ensure the effective use of your instrument!

Get a free demo