Complete the three-phase voltage and current measurement speed increased by 50%

雷竞技appFluke 377 FC and 378 FC clamp table is the first use Fieldsense ™ technology hand-held clamp table, can use jaw measuring voltage and current at the same time.This means that the clamp table can be used in continuous line of measurements and current measurements, to gain the line to line voltage to calculate the measured value and phase rotation information.These measurements can be instructed three-phase system is working as expected.

Simplify the relative phase measurement

L1, L2 and L3 (or line 1, line 2 and line 3) is wires in a three-phase alternating current (AC) system of universal naming convention.On the three-phase load, you need to use the wire measure the voltage and current in sequence.

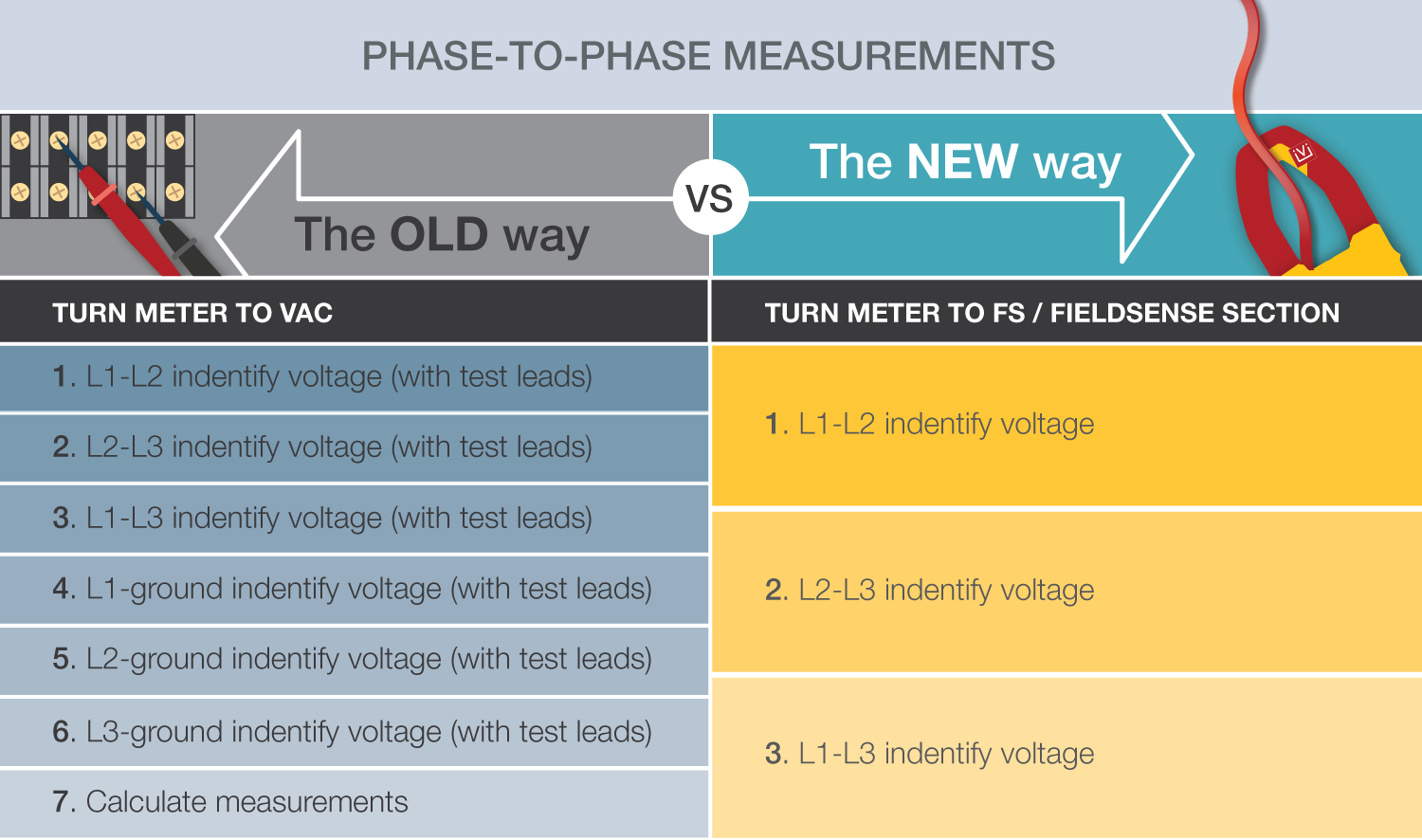

Current "choice - - write, choose - measurement - written" working process is very time-consuming.It requires you to all three phase repeat these steps.In addition, also need a third person or extra staff to help two wire connection, and writing values in the clip on the wire.

雷竞技appFluke 377 FC and 378 FC have revolutionized in the three-phase power system voltage and current measurement process.No longer need to use the test wire separately for each measurement and artificial calculation, now you only need to use pliers tables for measuring three times.Then, clamp table according to the relative measuring value automatically calculate the relative phase voltage for the whole.The clamp table is equipped with double show that can measure and display voltage and current at the same time.

How to make three phase measurement

Set up the

- Will spin to control knob

(Fieldsense ™)

(Fieldsense ™) - Using grounding wires connect clamp table to end

- Hold the MIN MAX maximum (minimum) 2 seconds.Clamp table now in line to line pattern, shown on the screenL1, L2, L3.

test

- Jaw set to the wires.Waiting for the measurements on the screen stabilize.The screen will become green, beeping, and displayL1.

- Moving jaw in 10 seconds into the second wire.Waiting for the measurements on the screen stabilize.You will hear a beeping and screen displayL2.

- Remove the jaw to the final in 10 seconds a wire.Waiting for the measurements on the screen stabilize.You will hear a beeping and screen displayL3.

To calculate

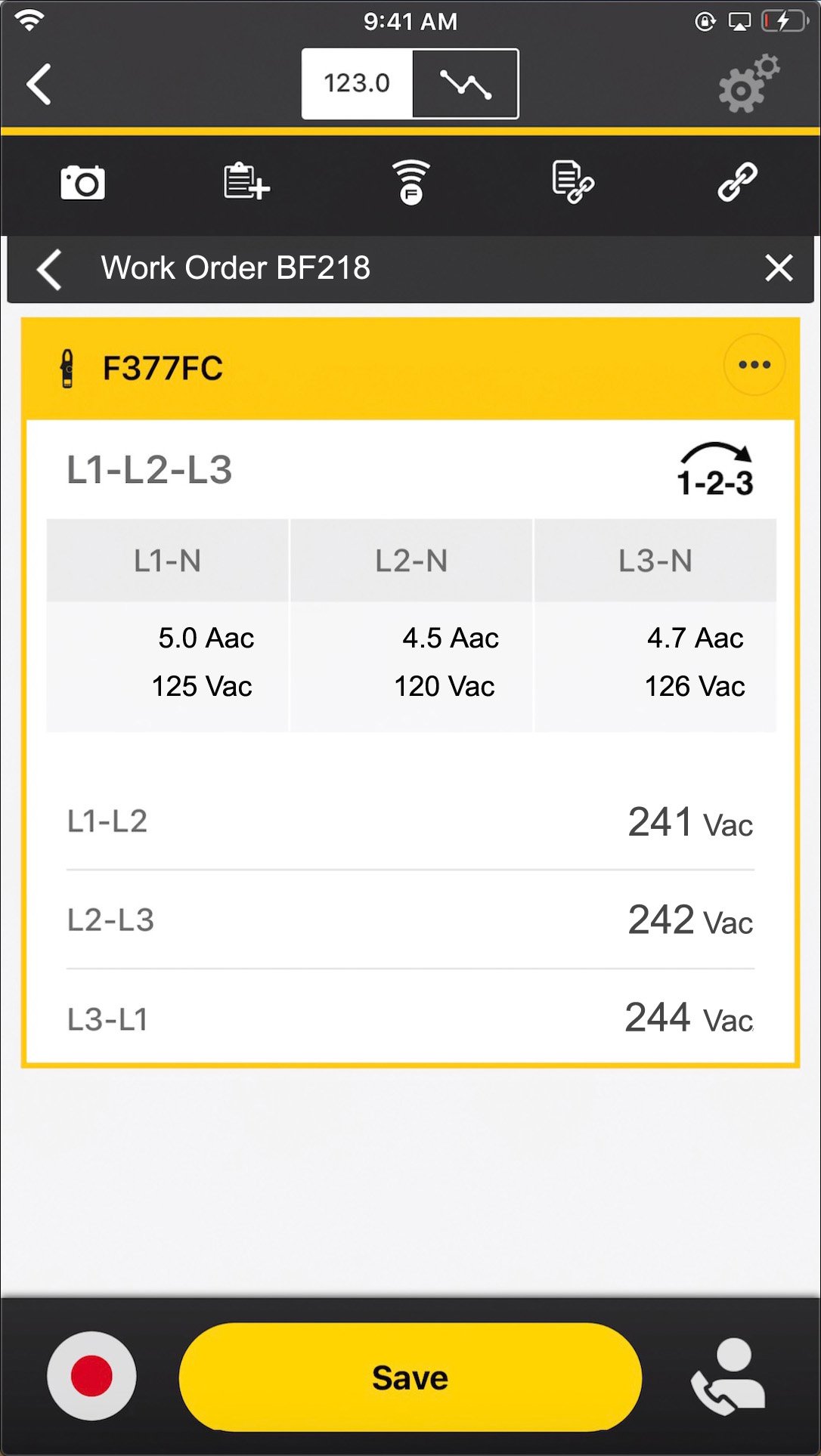

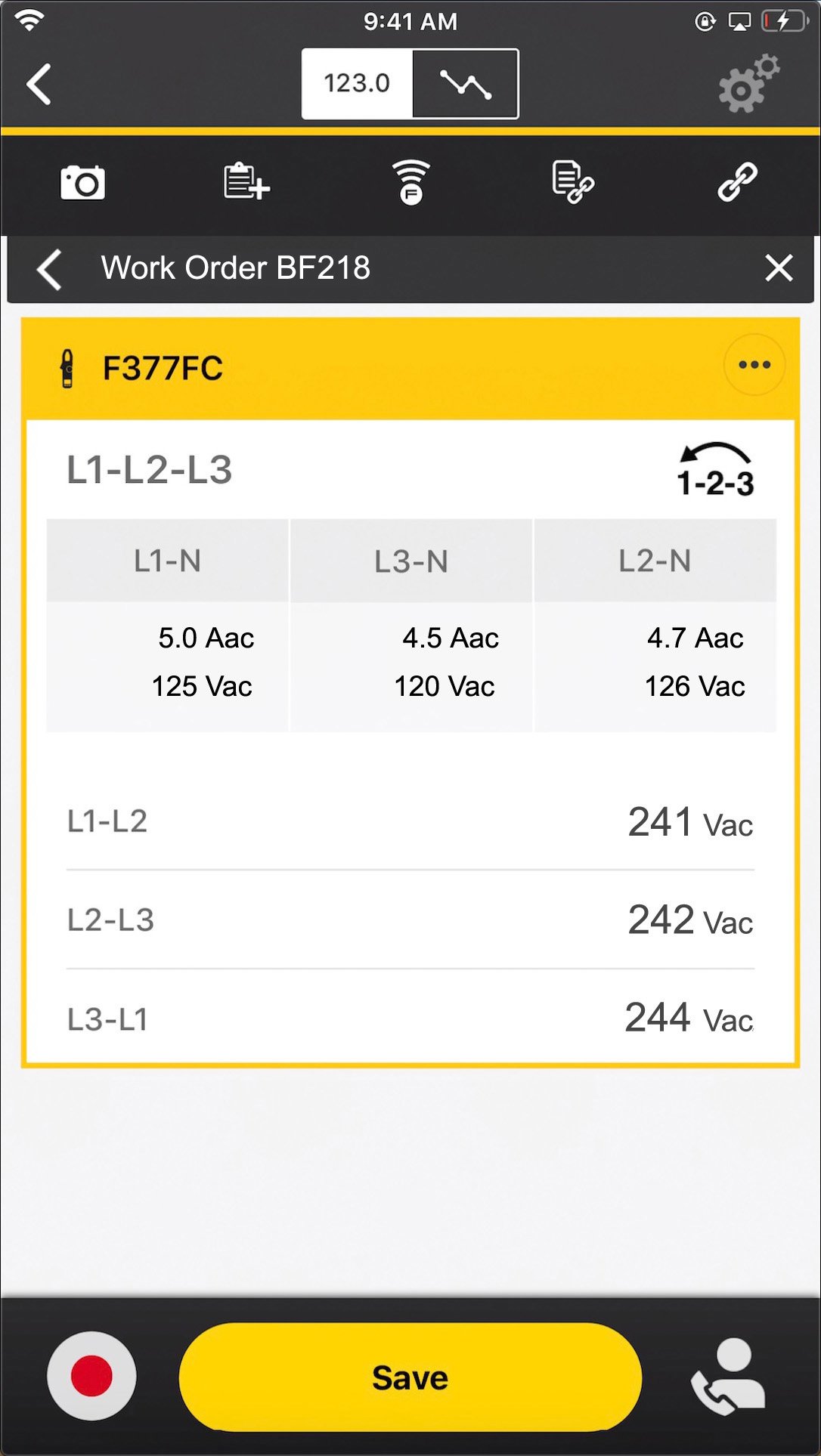

completeL1, L2, L3After measuring, clamp table is used to calculate the total voltage between each pair of wires:

- Press the MIN MAX maximum (minimum) a: screen display the total voltage between L1 and L2.

- Again according to the MIN MAX maximum (minimum) : screen display the total voltage between L2 and L3.

- The third time by the MIN MAX maximum (minimum) : the total voltage on a screen display between L1 and L3.

Is in line to line mode, you canFor each line of the measured values:

- Again press the MIN MAX maximum (minimum) can display L1 measurements.

- Again press the MIN MAX maximum (minimum) can display L2 measured values.

- Again press the MIN MAX maximum (minimum) L3 display measurements.

To see the L1, L2, L3 measurements, please continue to press the "MIN MAX" maximum (minimum) button and scroll through the measured values.

To withdraw from line to line mode, please hold down the "MIN MAX" maximum (minimum) button for about 2 seconds.

Phase sequence indicator function

Dealing with three-phase equipment, one of the biggest demand is to know the correct phase sequence, then make sure that during the installation, maintenance and troubleshooting in the correct order to complete the work.In additio雷竞技appn to simplify the measuring process, the Fluke 377 FC and 378 FC will automatically calculate the phase rotation.You only雷竞技app need the connection to the Fluke Connect (FC) when the application for all three phase measurement, then the phase sequence will automatically calculated and displayed in the FC applications.

application

The installation of hvac motor and compressor

Determine whether each phase during the installation process of load balance, phase rotation is correct.Unbalanced three-phase system can lead to premature motor poor performance or failure, resulting in costly downtime.Any point in the distribution system can appear unbalanced phenomenon.Should be evenly distributed between each phase of the incoming feeder circuit load.By the unbalanced power supply system of the operating temperature of the motor or the compressor will be higher, will eventually premature failure.

Rule out the fault of three-phase motor

Determine if a fuse is when fusing phase, phase failure.In the case of open phase, the other two phase will consume more current, so that the pump and motor winding overheating or compressor.By measuring the into the phase of the line voltage, the user can determine which phase failure, and help to prevent equipment damage.If happen during operation phase, because the other phase load will increase, then will start to overheat.If the equipment has stopped, the only and that there are all three phase again after replacing the fuse, device will restart.

* in the customer the field beta test showed that the three phase measuring the time required to reduce by 50%.